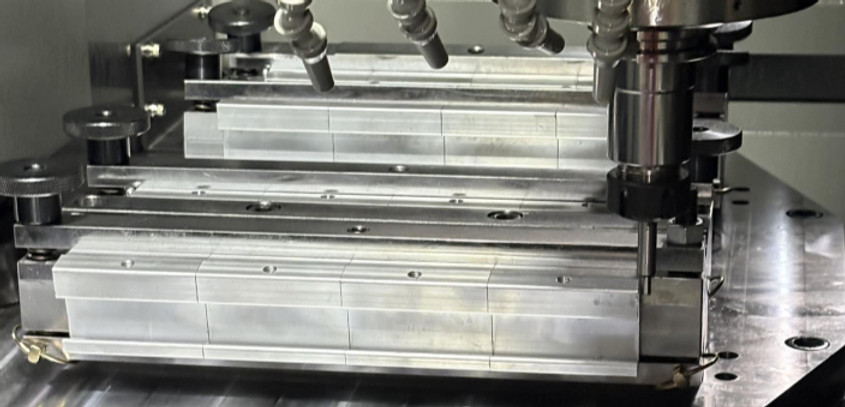

At H.M.E.-Tool we specilize in the design and manufacturing of custom fixtures that solve complex machining and manufacturing processes. Our precision workholding solutions are tailored to your unique needs, whether you are running low volume or high-mix production. We support vertical, horizontal, 5th axis fixtures and lights-out automation.

Custom CNC Fixtures

Design for Manufacturing

Affordable and Speedy Delivery

We approach fixture design from a machinist’s perspective. Having supported both production and one-off manufacturing, we understand the real constraints on the shop floor. Our fixtures are designed to simplify setups, improve tool access, and integrate cleanly with your machining process.

When parts are complex, we focus on keeping fixturing straightforward. Smart fixture design reduces build time, minimizes unnecessary features, and keeps overall fixture investment reasonable—without sacrificing performance or reliability.

Repeatable Accuracy

We design fixtures as if every part were headed to our own CMM. Datum strategy, clamping forces, and machining sequence are all considered during design to ensure consistent part quality and repeatable results throughout production.

Services

HELPING MANUFACTURERS EXCEL,

PART BY PART

Sevices

Custom workholding designed for repeatability and production machining.

Prototype and production CNC machining, supported by in-house fixtures.

Modular workholding plates for flexible setups and repeatable positioning.

Rotary solutions for multi-axis access and reduced setup time